Your Book Binding Guide

At Route 1 Print, we pride ourselves on being the best when it comes to supporting our resellers with book printing.

So much so that we’re always investing in the latest tech and equipment to ensure your client’s books come out just the way you envisioned. From our new Müller Martini Prinova Digital Saddle Stitch Liners to our recent investment in a new Horizon BQ500 MiniCABS and Renz Inline 500 Wiro Binder!

Explore our guide to delve into the intricacies of our book binding techniques. Each method is meticulously detailed, providing insights into its unique benefits and the advanced machinery involved.

Perfect Bound

Looking for highly premium and durable books at an affordable price? Perfect bound books are the ideal solution.

Renowned for their sleek and professional appearance, these books offer durability and can accommodate a higher page count of 450 printed pages, making them a fantastic choice for various printing needs, such as catalogues, novels, or magazines with a high page count.

The process of creating a perfect bound book starts with the print. All inner sections are printed on the Landa as pre-collated book blocks. After printing, the blocks are cut on guillotines, with yellow separator sheets added to help operators distinguish between blocks.

The blocks are then sent to the Perfect Binders, where they are paired with their covers and bound. Our state-of-the-art Horizon BQ500, part of the Horizon MiniCABS binding line, features a binder, loose block feeder, end sheet feeder, gauze feeder, and trimmer, all linked via Horizon’s ICE technology for fully automated job changeovers. Blocks are placed on the LBF belt, air is injected to separate the pages, and the block is “knocked up” before entering the machine.

Inside the binder, the block is clamped and scored along the spine, glued, and the cover is inserted and creased. The spine is sealed, and the book rotates through the machine before reaching the dispense belt.

The final touch comes from the HT-1000V Trimmer; our expert trimmer ensures each book is sized and trimmed to perfection before making its way to the conveyor belt, ready to be securely packaged and dispatched.

Don't forget you can enhance your client's book with options like foiling or Spot UV for an extra touch of luxury.

Stapled (Saddle Stitched)

When cost-effective, quick, and professional print solutions are needed, stapled booklets are an extremely valuable resource for print resellers.

This binding method not only delivers a hassle-free option for clients with projects demanding swift turnaround but also upholds a commitment to high quality. Adaptable to accommodate 8 to 72 printed pages, these booklets prove ideal for magazines, pamphlets, and small booklets.

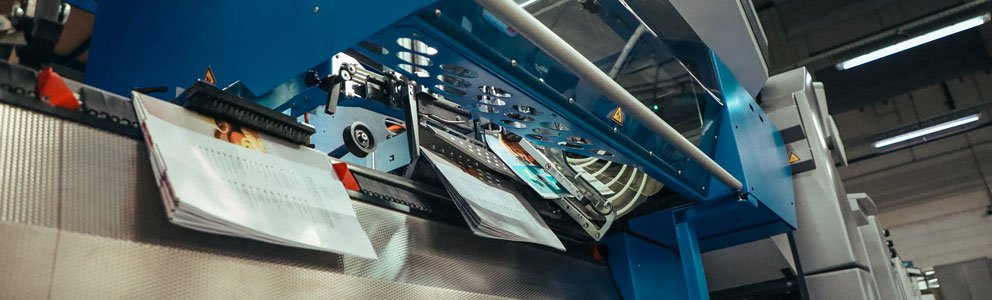

Our full range of cutting-edge equipment is utilised in the production of stitched booklets, ensuring that your client's artwork reaches its full potential.

Our arsenal includes two high-output Heidelberg XL106 B1 litho presses with LE-UV drying and both the nano-graphic Landa S10p and S11p, providing unparalleled flexibility and speed for any print run.

The stitching process is executed on the Müller Martini Prinova Digital Saddle Stitch Liners, guaranteeing the high-quality bound booklets you can proudly present to your clients.

The Muller Martinis are capable of being fed from any device in our factory, making them very flexible. We can feed the stitchers with reels and move from size to size automatically, and could also switch from reels to sections, to digital sheets.

We have 3 section folders that provide work for the Muller Martinis. Sheets are fed through the feeder into the first folding unit and are folded the required number of times. The folded sheet then passes through a second folding section, where a blade creates an additional perpendicular fold.

With a maximum of 16 pages per fold, section folding enables two-directional folds, ideal for artwork that needs to follow a specific flow or pattern, such as maps or instructional leaflets.

The machine is equipped with Hunkeler and Stahl folders, allowing pages to be cut to size and folded before being automatically collated and stitched.

The covers are then fed into the machine separately. Once the inner sections are collated, they travel along the saddle to the cover station, where the cover is applied, and the book is stitched. The finished book then passes through the three-knife trimmer to be cut to the final size, before being stacked and dispatched for packing.

Diversity is key in our selection of stock for saddle-stitched books, offering your clients a range of choices to achieve their desired booklet outcome. Plus, we extend options for lamination and embellishment, including soft-touch velvet lamination, spot UV and foiling, adding that extra touch of luxury to the final product.

Wiro-Bound

Wiro-binding stands out as one of the most cost-effective and user-friendly book binding techniques. In this method, a spiral or wire coil is threaded through perforated holes along the booklet's spine.

With the capacity to accommodate up to 400 printed pages, along with the added benefit of being able to rotate a full 360 degrees and lie flat, wiro-binding proves to be an excellent choice for notebooks, calendars, and manuals. This unique feature not only makes it easy to write on but is also ideal for day-to-day use.

To kick off the production process, we initiate by printing pages in pre-collated sets. Depending on the run length, we leverage the capabilities of either our HP Indigo presses or our Landa, offering you a diverse range of inner paper options and paginations.

The collated pages then undergo the punching process. Once the die is precisely set to the required dimensions, the pages are punched, preparing them for the next step.

Then our Renz Inline 500 Wiro Binder takes charge, delicately inserting wire through the punched holes to craft the final booklet. Our investment in the Renz Inline 500 Wiro Binder was a strategic move to enhance production capacity. This machine delivers higher-quality products faster and more cost-effectively. Precision punching and split dies reduce setup time, cut waste and speed up binding for books. Polished finishing features create retail-ready results your clients expect, while automated stacking keeps production moving when deadlines are tight.

Once the books are expertly bound, they make their way to our dispatch team for secure packaging and prompt dispatch.

Our wide range of stocks and sizes, along with flexible turnarounds, ensures that you can discover the perfect wirobound book solution for your clients.